本公司 1968 年由董事長張哲夫以一台車床從事加工開始創業,設廠於台中市忠孝路, 並於 1973 年進而製造車床,名為金和機器廠。1980 年遷移至現址 --- 台中市大雅區,並更改組織為金竑精密股份有限公司。 1996 年因應產量需求,另建CNC廠房。並於 1997 年正式啟用。為了符合客戶及場地需求,在 ” 台中市精密機械科技創新園區 ” 新購土地並於 2010 年年底開始動工興建新式的現代化廠房。

本公司創立於 2000年 11月由莊茂賓先生號召發起,尋找理念相同、業務相關核心人員,組織一個高效能的合作團隊,並推舉由莊茂賓先生擔任董事長,領導、執行公司各項業務及發展。

本公司自創立以來,即秉持著「專精、創新、實踐」的基本信念,不斷的努力經營。在領導階層帶領下,不斷的革新求變,以符合市場需求。並以科學管理增進效率,提高品質穩定性及最完善的服務系統。使「高品質、高效能」的新穎機械能深得客戶的讚賞、信賴與肯定。

和昕精密長期專於製造高精度CNC五軸分度盤。主要生產數控分度盤外銷歐洲,符合最嚴苛的歐洲市場標準,受到廣泛使用並深受各知名工具機製造廠肯定,為台灣最大的五軸分度盤供應商。秉持著「航太品質」「精益求精」「同理心」的品牌精神,致力提供最好產品及服務,以成為「加工精度的核心」為目標持續前進。

晶禧科技成立於2000年,專研於製造、研發CNC綜合加工中心機與五軸加工中心機,以國際品牌Sunmill(太陽銑床),活躍於國際舞台,拓展銷售版圖於全球達33個國家,長期耕耘台灣市場已屆二十年,並持續地開發超過二十餘款新機種與多項技術專利。

CNC Cutting Tool Solutions Supporting our Partners

Your cutting tools are the key step in your metal cutting process, so choosing the right long term manufacturing partner as your CNC cutting tools solutions provider will be key to your success and profitability.

奕達於2004年4月成立,至今事業版圖成長迅速,經銷體系遍佈全球五大洲,在全球化行銷為主軸的架構下,奕達積極培養團隊敏捷、專業、競合、樂於分享的員工特質,此外積極強化售後服務,迅速提供客戶滿易的方案,同時確保產品及技術的競爭力。

永進機械工業股份有限公司成立於1954年,累積超過六十年工具機專業製造技術,生產高剛性、高穩定的專業工具機,以「超高品質、尖端技術、全方位服務」為核心價值,持續設計研發優質性能與配備的工具機。

台灣榮田精機股份有限公司成立於 1987年,是以先進之科技,成熟的技術與經驗,生產 CNC立式車床(CNC Vertical Lathe), CNC立式車銑中心(CNC Vertical Turning Center ), CNC切削專用機及各種零件加工機生產線一貫作業的專業製造廠。

Accuway Machinery Corporation is one of the leading machine tool builder of vertical machining centers and CNC lathes for various industrial applications. Founded in 1986 by supplying mold and die for semi-conductor industries, it has accumulated abundant precision machining experience and technologies by continuous improvement and innovation.

堡豐工業股份有限公司成立於1986年,以傳統式銑床為主,為配和國際市場需求並提昇經營層次,堡豐不斷引進新設備及新技術,至目前為止已研發出高品質之傳統及CNC銑床。

專精 創新 實踐<br />S5A-4732HH, 專為加工鈦合金及難削材料等五軸加工零件而打造的重切削型CNC五軸龍門加工中心機; 全機身採高剛性結構體設計, 機械式同動二軸頭, BC軸傳動採蝸桿蝸輪傳動, 搭配自製重切削式兩段變速齒輪箱及齒輪式傳動主軸設計, 最大重切削扭矩可達到1155N-m; 主軸頭軌道設計獨家專利-切削加工抑制振動結構設計, 降低難削材料加工的振動, 提升加工效率、表面精度與刀具壽命; 全封閉式防濺鈑金護罩, 摺疊式操作門且具備超大門寬設計, 整體外觀更結合時尚美學及安全防護的人因設計; 橫樑安全護欄設計, 保護維修人員安全, 方便機械維修作業; 升降式懸臂操作箱, 可隨時調整高度, 配合操作者所需。<br />

追求易操作性與高品質零件, 結合多軸、高精度、高效率與高性價比等多項特色, 特別針對生技醫療、汽、機車與高精度等中小型精密零件產業所開發出新機種, 可輕易完成複雜工件之加工並結合自動化模組, 提供客製規劃服務。

*詳細規格請點閱 www.yidacnc.com

*詳細規格請點閱 www.yidacnc.com

PF-8S1500 CNC 4軸CNC 床台式 銑床工作臺尺寸: 1730 mm x 400 mmX 軸 行程 : 1500 mmY 軸 行程 : 500 mmZ 軸 行程 : 550 mm

2080/3080 CNC蝸(螺)桿磨床是邁萃斯精密(股)公司,運用累積多年發展齒輪刀具加工設備的專業技術,及結合最新科技產品,以電腦數值控制器結合個人電腦,搭配線性馬達(Liner Motor)與直驅馬達(Direct Drive Motor ) 的特性,所研發出四軸數控的高精度磨床。邁翠斯自行研發的智慧式交談視窗軟體,可靈活設計出您所需要的齒形修整及輪磨條件,可做雙導程蝸桿輪磨、單邊輪磨、不等壓力角蝸桿輪磨、螺紋塞規及輥牙輪輪磨等功能。智慧軟體還可妥善管理儲存工件規格,輪磨參數及修砂數據,除標準化的蝸桿齒形外,亦可彈性修改各式理想齒形,此外齒頂齒底皆可輪磨與修形,並可進行砂輪修整以利各種複雜工件之加工。WT系列 CNC 蝸 (螺) 桿磨床是您生(量)產線上之最佳選擇。

3040 CNC數控滾齒刀磨銳機是邁萃斯精密(股)公司,運用累積多年精密齒輪設計製造及齒輪刀具製程設備發展的專業技術,結合最新的科技產品,如:AC伺服馬達閉迴路控制與扭矩馬達伺服驅動技術、及可整合工業用電腦的控制器系統,所研發出高精度、高效能的臥式數控滾齒刀磨銳機。除可執行直槽,螺旋槽等各式滾刀刃口磨銳。同時亦可依客戶之特殊需求在本機型上增加應用插齒刀刃口磨銳等複雜工件輪磨之功能。操作者依據電腦上圖示化的人機界面指示步驟輸入所需參數,無需程式編寫訓練,所有輪磨加工程序的NC程式會自動產生。此系列 CNC 滾齒刀磨銳機是您量產線上之最佳選擇。

各類型機械手加工製程上下料整合,CNC自動上下料應用與相關周邊設備規劃,製程設備搭配AI智能管理系統,將系統結合資料庫及雲端,分析各種數據及重要資訊並依照需求客製化呈現,便於系統監控與管理使生產智動化。更多請參考:www.dsa-auto.com.tw

High Precision, High Quality, Focus on the Future

Accuway was founded in 1986, supplying molds and dies for semi-conductor industries. It has accumulated abundant precision machining experience and technologies by continuous improvement and innovation. Through this rich experience, in 2002 began to develop and produce CNC lathe and vertical machining centers for versatile industrial applications.

Accuway products have won a wide reputation and positive feedback from a broad range of customers, especially within Taiwan, China, North America and Europe’s competitive markets.

Accuway is seeking to be a leader in the precision machining tool industry, providing integrated, state-of-the-art, automation technology with best solutions to meet the challenges of industry 4.0.

We can provide customers with advanced and efficient manufacturing solutions to provide excellent productivity and versatility. We use the most advanced design techniques to ensure that products have a high level of performance, production, and quality control.

We are represented in all major markets with sales and service bases and qualified service partners.

Our customers include companies from the automobile industry and their suppliers, from general mechanical engineering, energy technology, fluid technology, aerospace and many other sectors.

Accuway’s aim is not solely to produce and sell machines. It involves collaboration in synergy with our customers. This applies to everything, be it internal or external, so that together we can rise to meet their challenges and actively help them succeed.

UZ/UA Series - Multi-axis Machine Center for Mass Production

Increase Your Working Range with large Y-axis on Upper & Lower Turrets

A. Structure

Twin Spindle, Twin Turret

This machine offers multi-axis machining of complex parts with twin, 16-tool power turrets. Twin turrets and a shared Y-axis allow you to produce complex parts with high precision without having to transfer the part. Higher productivity coupled with high accuracy equates to higher throughput and profit potential for today's competitive machine shops.

Twin Y-Axis Machining

The Y-axis control and simultaneous machining capability offers significant advantages over standard machines, allowing it to produce a wide range of complex precision parts.

Flats cannot be machined if there is no Y-axis control to precisely position the cutting tool in the correct orientation on the inner circumference. With a Y-axis control to precisely position the cutting tool, flats can be machined with precision.

B. Specifications

Gear-driven BMT live tool turret

Opposed two-spindle, 2-turret construction

Y-axis on upper turrets 110

16+16 tools changeable tool station

One-piece bed, 45° slant-bed structural design

Distance between spindles: 900mm

Max. Swing: 660 mm

Max. Length: 480 mm

Spindle: A2-6 in 4500 (Belt)

Bar capacity: 52 mm

Main spindle motor 11/15kW (Belt), Sub spindle motor 7.5/11kW (Belt)

C. Applications

Automotive: Camshafts, Linear Guide way, etc.

Construction Machinery: Spool

Industrial Machinery: Sleeve

Agricultural Machinery: Flange

Aerospace Parts

D. Model Reference: https://www.accuway.com.tw/uz-series.htm

About Maintech Precision

Maintech Precision focuses exclusively on the manufacturing of high-end CNC machine tool milling heads. Recognizing the rise of industrial 4.0 and artificial intelligence, we committed to automation and artificial intelligence research and focused on developing complex spindle heads for high-end CNC machines.

We provide our customers with expertise in multi-axis machining applications, and have a complete range of milling heads for five-axis processing machines. We are committed to cooperating with our clients to design and manufacture customized products with high added value, and to providing faster, more economical after-sales service, at a price in line with customer expectations.

We currently supply milling heads used in 5-axis CNC machines used for aerospace and aviation applications, precision molding, or for wind turbine blades. We offer an alternative to the 2-axis spindle heads currently imported mostly from Europe, by providing suitable products and services designed for the Asia market, eliminating the long repair cycle and high maintenance cost of other manufacturers.

Maintech Products

Mechanical spindles

Automatic milling heads

Electric spindles +DD Motor

Five-axis milling heads

Maintech Product Features

Maintech plans and designs the interface between the machine tool and the milling head, making installation easy and simple.

Our mechanical spindle speeds of up to 6000rpm are among the highest in the industry.

Sensor detection inside the milling heads, which meet the needs of Industry 4.0, allow the rapid exchange between various types of milling heads to be realized.

According to the specifications of the machine tool, milling heads are divided into medium and large, and can meet the needs of small as well as large machine tools.

The minimum segmentation angle of A/C axis is 1 degree, for highly reliable stability.

Technical Advantages

Technical Service

Maintech has the ability to design machine tools + two-axis spindle heads. If a manufacturer only produces a single milling head, when the milling head is installed on the machine tool, there will be a precision error after the machine tool and milling head are matched. By designing machine tools with two-axis spindle heads, Maintech can avoid this problem, and provide professional and fast technical services to assist customers in troubleshooting.

Quality Assurance

All parts inside the milling head are measured in the factory to ensure the accuracy of the processed parts. Rotation speed and movement flow are completely verified for accuracy before the product is shipped.

Applications

Mechanical Milling Head

For high torque heavy cutting of difficult-to-cut materials.

Features:

It can reduce the need for repeated clamping of the workpiece, improving machining accuracy and efficiency. It is mainly used for Machining Centers and five-sided machining with gantry milling machines.

Applications Areas:

Wind power and hydropower industries

Rough processing of aerospace industry processes

Automotive industry

Electric Spindle + Direct Drive Motor

For high speed and high precision cutting.

Features:

The built-in electric spindle + direct drive DD motor is suitable for surface processing and high-precision processing required for finely finished surfaces.

Applied for low and medium load fly-cutting of aluminum alloy and composites.

Application Areas:

Processing machinery for electronic products

Aerospace components

Aerospace blade and vane processing

Precision molds

Maintech Precision is a specialist in the field of complex spindle head for high-end CNC machine focusing exclusively on the manufacturing of high-end spindle heads. We are sure we can definitely to fit your needs.

KINWA Brand, Worldwide Reputation of Quality

KINWA LATHE was established in Taichung City in 1973, manufacturing precision high-speed lathes as its foundation, in 1980, we moved the factory to Da-Ya District and reorganized as CHIN HUNG MACHINERY CO., LTD. Since 1990, we have been developing and manufacturing CNC lathes, greatly expanding our market presence. The KINWA brand has gained a well-known, worldwide reputation for high quality lathes.

KINWA’s broad range of excellent quality, high-speed precision lathes are found as standard equipment throughout many Taiwan and overseas manufacturing industries. With the development of CNC lathes, KINWA’s popular, high-tech, Gang-Type and Flat-bed CNC lathes have become essential the manufacturing industry. Over the years, KINWA LATHE has made huge progress in designing and providing customized precision high-speed and CNC lathes.

As the demand for automation growing, KINWA LATHE’s abundant experiences in precision lathe manufacturing enable us to help customers of hand tool manufacturing to plan linear robot automation of lathes and also to cooperate with customers who manufacture home appliance parts to use vibrator bowl to achieve the purpose of automation. Furthermore, we work with a world-famous shock absorber corporation to plan automated load/unload robots to accomplish the purpose of automation to increase productivity and yield rate throughout the entire plant.

With the post-pandemic price of raw materials continually raising, KINWA LATHE still insists on using components made in Taiwan by local manufacturers. We are keeping our commitment to providing only the best quality products and service for our worldwide customers.

Want to save time on your milling operations, but aren’t ready to make the large investment required for a CNC milling machine? There is an efficient option.

Realizing the large price difference between “Traditional Milling Machines" and "CNC Milling Machines," and seeing the lack of intermediate products on the market, PaoFong focused on the design and manufacturing of Numerical Control (NC) Milling Machines that automate many traditional milling operations.

By incorporating relevant controller systems, many traditional, manual, or electric milling machines can be upgraded to smart automatic milling machines. Using G and M code editing programs, or CAD/CAM translation processing programs, workpieces can be mass-produced, while maintaining the immediacy and convenience of traditional milling machines. Based on a traditional milling machine structure, these machines are easy to maintain, and parts are easy to obtain.

The 15-inch, touch-screen control panel can interface with either a wired or wireless universal computer keyboard. The interface is easy to operate and can be customized to closely meet the user’s needs. The “Smart Machine” can use an API and CNC smart box, with a wired or wireless network, to allow the server to access the controller information and share the data with relevant decision makers.

All these features make for a very efficient milling machine that can do multiple processes, all at a very affordable price.

Pao Fong Industry Co., Ltd., established in 1986, specializes in the manufacturing of conventional milling machines, NC milling machines with CNC machine tools, and milling machines with Simple Automatic Control. Pao Fong’s innovative R&D designers, offer high-efficiency and high-quality machine tools for all customers.

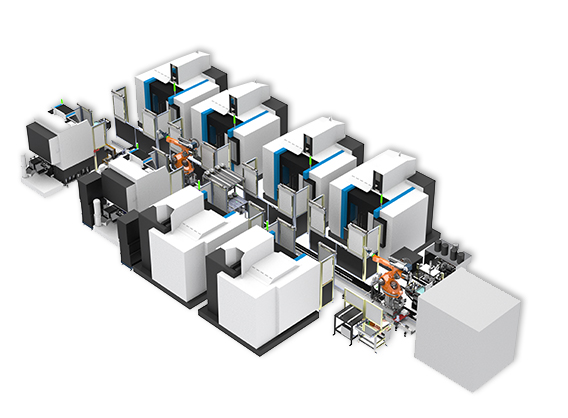

Smart Factory Solutions for Metal Manufacturing

Innovation, Technology, Science and Customization

Established in 2013, Da Shiang Automation (DSA) is located in Guishan Industrial Park, Taoyuan, Taiwan. With the business philosophy of maintaining an Innovative, Technical, and Scientific Spirit to service our customers, DSA continues to grow.

As a highly skilled system integrator in automation, with software and hardware technical skills, DSA has more than 10 years of experiences in Investment Casting, Sand Casting, Die Casting and Machine Tending…etc. Below are 6 major services we provide:

AUTOMATIC SOLUTIONS FOR INVESTMENT CASTING, SAND CASTING, AND DIE CASTING PROCESSES

DSA provides turnkey solutions for casting automation, and is fully experienced in investment casting, sand casting, and die casting processes. Also, we offer complete hardware & software integration solutions for the setting up of a smart factory.

Automatic Solutions for Investment Casting Processes

Through the automated system integration of wax mold, shell mold, and casting processes, using robots to replace manual work in high-risk operating environments, we help improve production quality. Features of various systems include:

Wax Mold Process Automation

Fully automatic production, from wax molding process to wax tree assembly, can save manpower and improve production efficiency.

Shell Mold Process Automation

The system identifies the state of the shell mold through RFID and automatically integrates the dipping, coating, and drying processes.

The AI management system offers automatic parameter settings for shell mold processes.

The vertical conveyor drying room, with flexible production, can optimize the procedure of drying and save space.

The shell mold can be dried faster and maintain better quality by the design of the wind field.

Infrared Shell Mold Rapid Production System

The modular and parametric design can be used for various products.

It takes 50 hours to dry shell molds using traditional processes; however, it only takes 6 hours to complete drying with this system.

Compared to other traditional shell mold processes, it gives better quality.

Size, weight, and quality are standardized and stable.

Automatic Solutions for Sand Casting Processes

Provide the complete sand-casting automation process can contain the following: cold-core coating, laser marking, dispensing & molding assembly, screwing, handling system for sand casting.

Automatic Solutions for Die Casting Processes

Labor in high-risk environments can be replaced by integrating several die-casting processes with robots.

AUTOMATIC SOLUTIONS FOR POST-TREATMENT OF MACHINING & CASTING

DSA also provides turnkey solutions for post-treatment of machining & casting, and is fully experienced in deburring, grinding, polishing, sandblasting, and cutting.

Robotic Deburring, Grinding & Robotic Cutting Systems

Deburring & polishing for grinding gate, runner, parting line & weld bead.

Increasing productivity and safety, and saving labor.

Robotic Sandblasting Systems

Robotics, integrated with sandblasting systems, enhance quality and save labor. A second robot can also be integrated for loading/unloading, increasing automation of production.

AUTOMATIC SOLUTIONS FOR MACHINE AUTOMATION PROCESSES

DSA is fully experienced, and provides a third turnkey solution for machining automation.

CNC Machine Tending System

Machine Tending Systems with Linear Units

Enhance productivity by automation.

Automate design for turnkey projects.

Give a wide working range with external axis.

Provide appropriate automation solutions.

Approach real-time monitor and equipment status analysis by adding a DSA SCADA SMB system.

Introduce automatic production scheduling to achieve the best production efficiency.

Gantry Robots

Customized X, Y, Z axis work range.

End of Line Machine Automation

Integrating after-machining processes, such as deburring, measurement, leak detection, cleaning, assembly, and laser marking. Integrating the vision system to reduce fixture using and increase production flexibility.

CMM Machine Tending Automation Systems

Flexible pallets with RFID, barcode or vision systems can be applied in mixed lines. PLC system controls the CMM to achieve measurement automatically.

Above are our major services. Furthermore, in order to provide advanced smart automation solutions, DSA has integrated industry 4.0 concepts to casting and machine tending operations, to better fulfill customer expectations. We will keep improving to provide complete solutions and services for you.

本網站使用瀏覽器紀錄提供最好的體驗。相關資訊請瀏覽我們的隱私權政策。